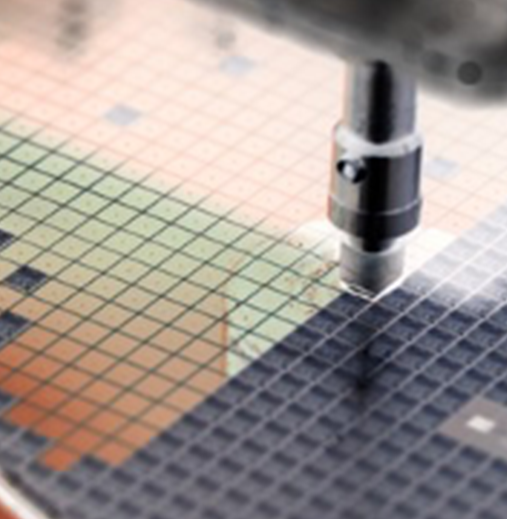

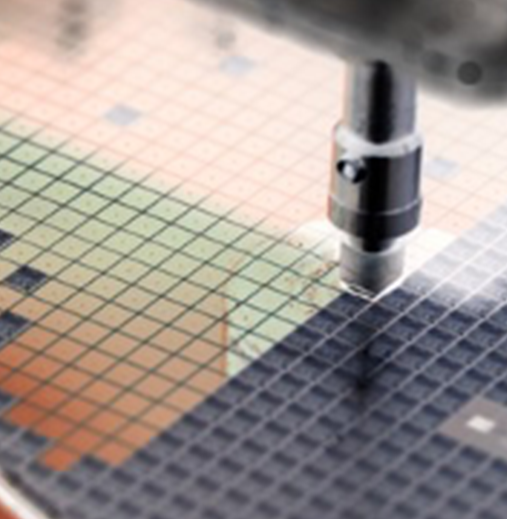

Die attach is the foundation of the assembly process; it is the first critical step in the process and getting it right is essential for a reliable finished product. Die-Attach processes available at AVANT MICRO SYSTEMS:

AVANT MICRO SYSTEMS partners with customers to provide them with the highest-quality IC assembly services to achieve their goals. We help companies introduce their new products to market in the fastest time possible by providing high quality, quick-turn assembly. AVANT MICRO SYSTEMS assembles ICs in prototype and production volumes to help you qualify your designs and provide quality samples to your customers.

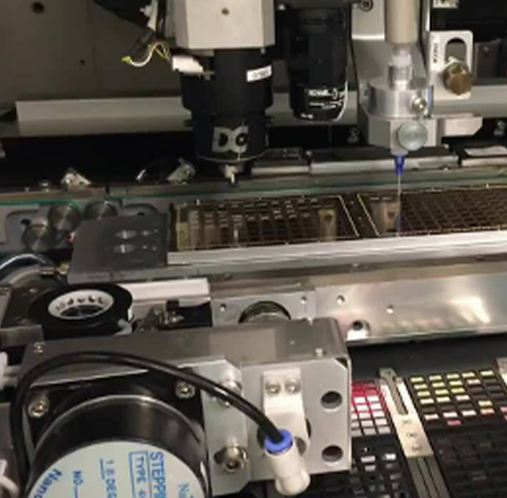

AVANT MICRO SYSTEMS understands that time is of the essence in this fast-paced technology. We use state-of-the-art machines in our facility to support and turn many different types of IC assemblies in as quickly as 4 hours. Our flexibility in meeting customer requirements and our superior customer service separate us from all other assembly subcontractors worldwide.

The type of material and method of attachment used to encapsulate a device can be critical in determining the completed package class. At AVANT MICRO SYSTEMS, we offer a large variety of encapsulation options to meet all our customers’ requirements.

For quick-turn prototyping, AVANT MICRO SYSTEMS is unsurpassed in producing highly complex products such as Flip Chip or wirebonded BGA or chip-scale devices with thousands of bumps or wire bonds. For new product development, where time-to-market is of utmost importance, especially in highly competitive markets, AVANT MICRO SYSTEMS customers will request quick-turns as fast as 8 to 24 hours. This leads to faster introduction of customers’ products into the market resulting in greater market share and increased profitability for our customers. AVANT MICRO SYSTEMS is the sole source provider of prototyping services in Flip Chip and wire bonded BGA’s for many fabless companies as well as full IDMs (Integrated Device Manufacturers with wafer fabs) and OEM’s with application specific devices. AVANT MICRO SYSTEMS also is the designated provider for pre-production quantities, overflow production, and for end-of-quarter or end-of-year production surges for many customers.

For quick-turn prototyping, AVANT MICRO SYSTEMS is unsurpassed in producing highly complex products such as Flip Chip or wirebonded BGA or chip-scale devices with thousands of bumps or wire bonds. For new product development, where time-to-market is of utmost importance, especially in highly competitive markets, AVANT MICRO SYSTEMS customers will request quick-turns as fast as 8 to 24 hours. This leads to faster introduction of customers’ products into the market resulting in greater market share and increased profitability for our customers. AVANT MICRO SYSTEMS is the sole source provider of prototyping services in Flip Chip and wire bonded BGA’s for many fabless companies as well as full IDMs (Integrated Device Manufacturers with wafer fabs) and OEM’s with application specific devices. AVANT MICRO SYSTEMS also is the designated provider for pre-production quantities, overflow production, and for end-of-quarter or end-of-year production surges for many customers.